MGDL

or

Fun with Diamonds

Diamonds may be a girl’s best friend but the wood worker’s among us can have lots of fun with projects using diamonds to make dynamic wood art.

Multi Generational Diamond Lamination (MGDL) is the process of gluing multiple first generation laminations into both vertical and circular design patterns.

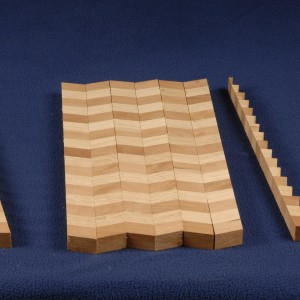

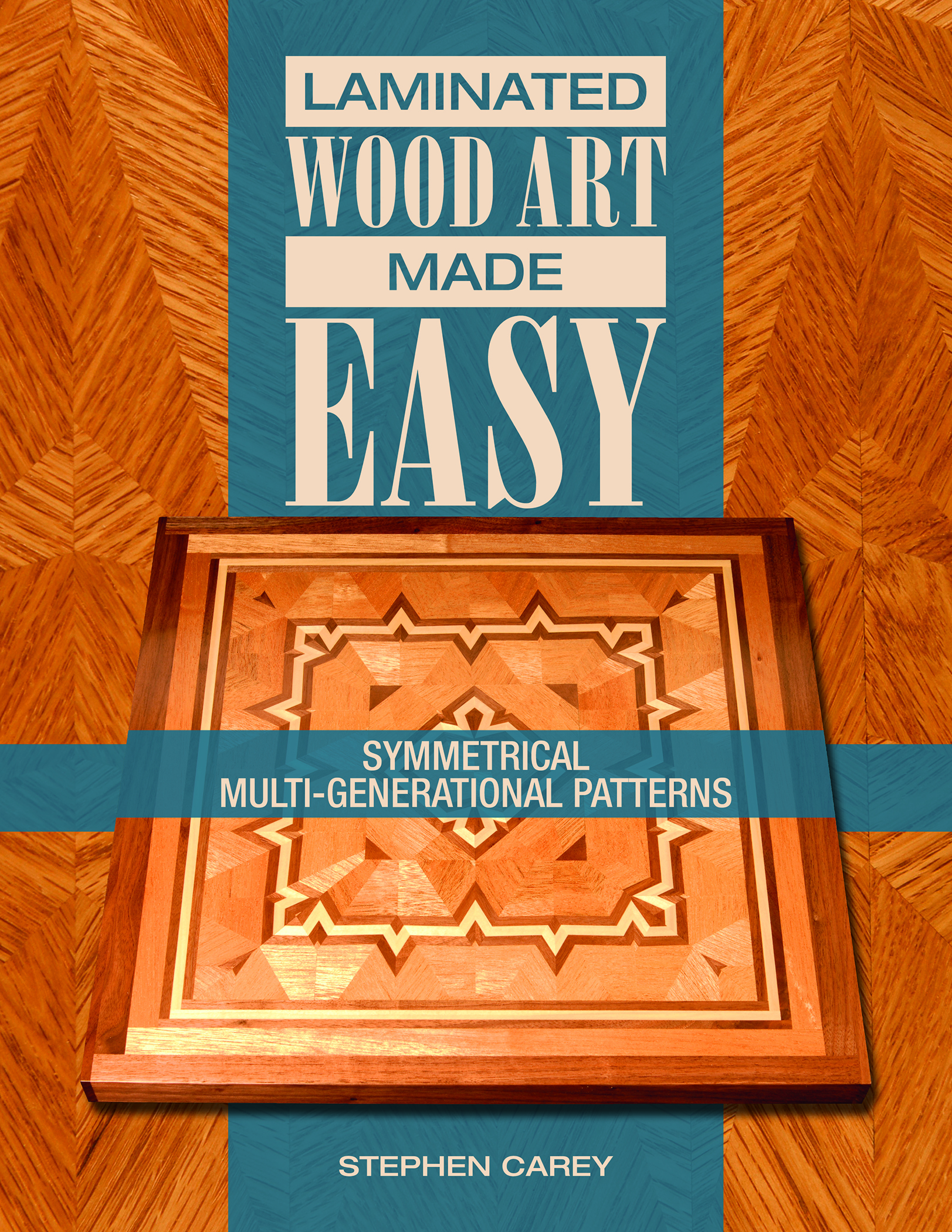

Believe it or not these designs are made with the same material and with the same construction method. The diamond orientation differs, but the parts and pieces are the same. On the left you see the vertical or linear orientation and on the right a circular design. The difference from top to bottom is simply different finishing techniques which can be employed. These 4 designs represent a small fraction of what is possible in variation and expression in the endless array of designs possible using this technique. While working on one design I am taking notes on the next 4 projects I want to try.

With these lamination projects we are focusing not on making something in particular rather, we are ‘making something to make something’. To create the above material is a wonderful beginning to a beautiful ….. whatever. Whether lazy Susan, cutting board, platter or a vase, bowl or plate all would be fitting uses for this wonderful, colorful material. For all woodworkers whether you have a lathe or not, this type of project is nothing but fun. For our purposes we will focus on the making of these blanks above and allow the wind to carry your application of it where it will. I beg you though, comment and let me know how you were able to apply these techniques.

First we need to determine how many varied colors and wood types to involve. I have chosen 6 for this project but 4 is a better number to start with as with my first try at this seen above. Here the diamonds are larger and easier to work with but it uses 4 types of wood with the same basic circular 8 pointed star pattern.

As with all these types of projects its success is centered on all the material being the same width and thickness. Also best results come from using wood with a similar density and relative hardness. Combining poplar or pine with Iron wood or purple heart is not recommended. The material must be spot on in dimensions and be sure and make up twice as much as you think you’ll need.

Above you see I have milled up cherry, ash, walnut, black locust, Brazilian cherry and Brazilian walnut. The more contrast in the wood the better the woods augment each other and the designs stand out.

With the material milled we can begin to make the first generation lamination. These six are laminated together as below.

Notice here that each lamination is different. Each one in sequence moves the top most wood to second position and the bottom wood to the first position. Thus you are making six sequenced laminations. Follow the darkest wood and you will see that with each of the six glue-ups it is in a different position. They are ordered in a step fashion.

Now that our material is ready let’s get started.

What is a diamond?

There are many ways to answer that question but for our purposes, diamonds share a common length along each of its 4 edges, like a square whose top has been pushed over by the wind. Now this sounds easy but it is not. In order to accomplish this you need to pay close attention to the width of the material because the width will determine the length of the 2 edges which are along the cut or mitered sides.

Your project will be determined by the center set of diamonds in the round. Like building any round object we begin from the center and work out. Here we are looking at 8 diamonds all pointed to the center. 8 divided by 360 degrees is 45. So each piece will contain 45 degrees. Since each diamond has 2 sides which connect on the edges moving towards the center we will divide the 45 degrees evenly for a diamond with all its edges at 22.5 degrees. That is pretty much the end of the math. This math can apply to any number of center pieces. For example , 10 center pieces at 36 degrees each with cuts at 18 degrees. The difficulty is in getting a perfect cut from your table saw miter jig or your miter saw. Practice and cut scrap until you have a perfect 8 pointed star with no gaps or spaces on the interior or exterior. Remember , cumulative error is to be avoided, so the time you spend getting it cut just so , pays off down the road.

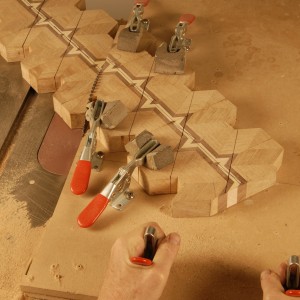

Once our miter is ready we can begin cutting diamonds 6 at a time.

Weather table saw or miter box this process must be precise and consistent. Uniformity is the key.

Notice here the 6 laminations sequenced to form the linear design. The circular design is simply a different order of the ‘Tags’ (what I call each cut section of 6 diamonds).

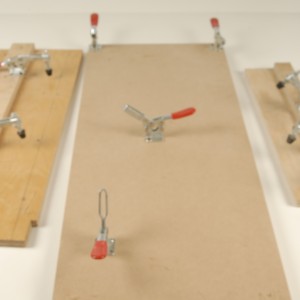

that we are more comfortable with the design we can get the glue bottle out. We begin with a diamond of diamonds. With all projects like this it is always best to glue in stages and steps. In this case, larger diamonds.

Notice the rubber bands and glue boards. Because the shape of a diamond will not support glue pressure on its pointed ends these ‘outriggers’ so to speak are necessary

Above the finished diamonds form the linear pattern

Beginning to take shape

And here you have it. It is important to trim the unfinished 2 edges to make these stars come together perfect. A miter or table saw jig work well for this as will a disk sander.

Care must be taken maintain the exact 22.5 degrees and not to remove so much material as to disrupt the overall design pattern.

In the interests of time and space and knowing a picture is worth well over a thousand words, especially to a wood worker I will show more and talk less.

A dry fit up showing both finishing techniques. One with a continuation of the linear pattern and the other with a simple section of material cut to fit.

I have found the best way to finish and flatten these is to use a belt sander.

I hope you have found this posting helpful in opening up new dimensions in woodworking. It is one of the most fun projects I have enjoyed for some time. Remember if you try it be sure and let me know how you did.

Always gluing something:

Steve