Placing as design or pattern in a vessel

Placing as design or pattern in a vessel

I get a lot of questions during my presentations and woodworking talks and one that pops up almost every time is ‘how did you do that’ while pointing at a design inside a bowl or vase. How do you take some design that is flat and make round? Good question!

Using the tumbling block design below I will try to go through some of the steps and methods of doing this without going to deep into the ring construction method used to make the rest of the vase.

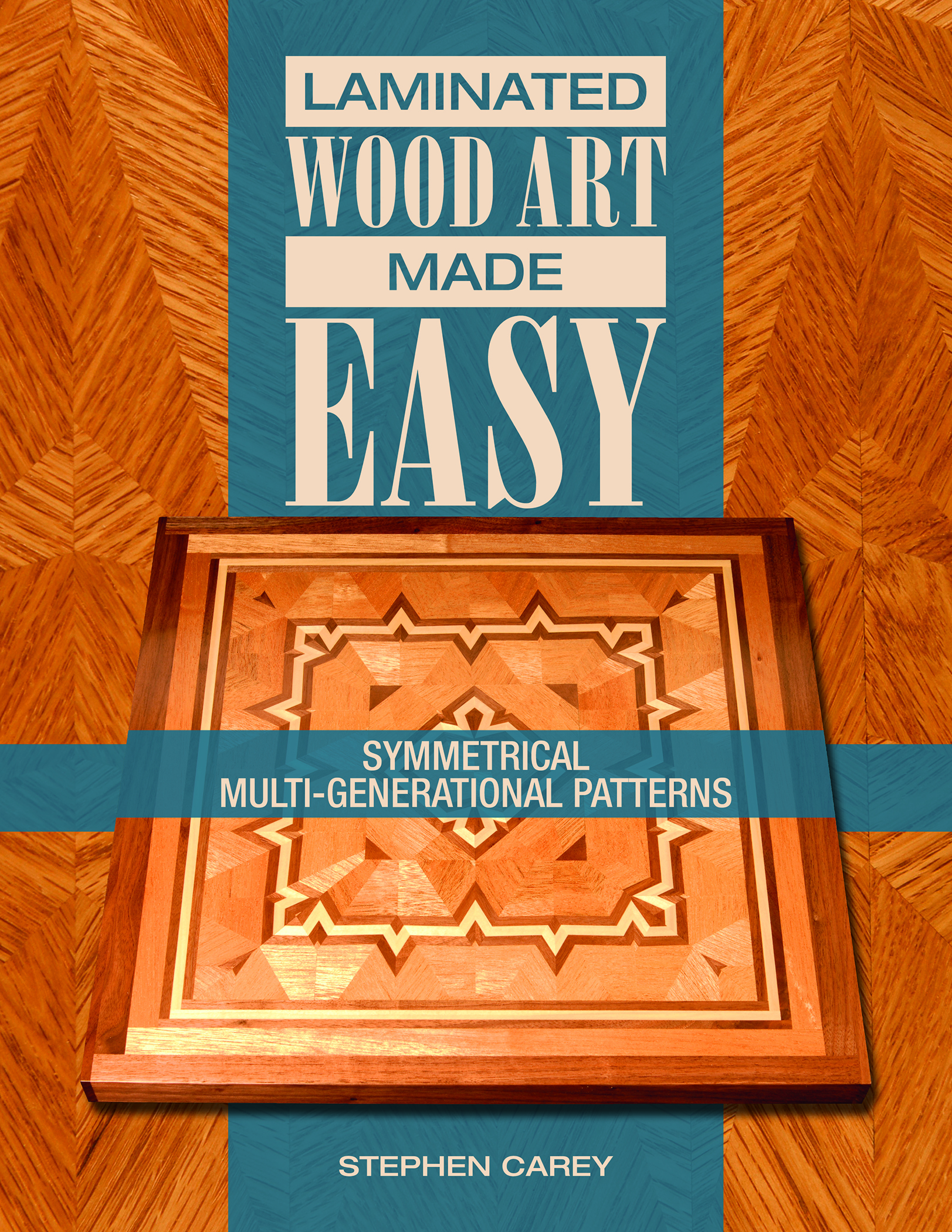

Above you see the cutting board everyone likes, a basic tumbling block, 3D pattern that is fun to do. Now let’s think about placing it into a vessel.

See below that we have already completed the difficult process of getting good clean diamonds whose 3 parts or diamonds form a single tumbling block.

We then can use these same angles to make diamonds for the top and bottom and longer pieces for the sides. Essentially we are surrounding the design with the same material as our vase. Be mindful during construction to keep the patterns uniform and be sure and make a couple extra as some are bound to be less tight and appealing as others.

Here we are laying out and preparing for the glue up. Remember as you make these single designs you are making one of eight (depending on what you use for a degree and design look, meaning you could form many or more designs in a single highlight ring depending on the look you are after determining the degree of your cut) which means your are determining your vase diameter by the length of the design. Best to start with a vase diameter, determine its circumference and divide by 8 giving you a ball park for the distance from left to right of each design piece.

Here you see it with its rings on the right that will form the sides of the vessel under and over the design ring or highlight ring (I use these interchangeably as the designs are the highlight and they form a ring (one of several) within the vase).

Prepare for the glue up by getting everything in place and each design uniform. Checking for tight joinery and getting the rubber bands out. I use rubber bands for this type of glue up. 6 or 7 thicker ones are more than enough to get you great results. If not the problem is your cutting and accuracy of miter not more clamps.

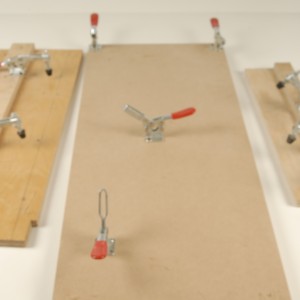

This next step requires cutting jigs. If you have been to one of my presentations you know how I feel about jigs, all kinds of Jigs. Here I will be laying out MDF for a precise cut making the top and bottom uniform and accurate according to the design in the middle. This cut will then be the basis of the right and left hand cuts so this one is worth getting right.

I love double stick flooring tape which you can get at any Home Depo / Lowes.

It holds everything in place nicely. Remember you are lining up the center design here not the edges of the glued up piece. You want the designs in the center to line up more than just cutting off the bottom and top. The jig will allow you to move the pieces and hold them in place in a way to insure the uniform look of the design in the center of the highlight ring.

Above I have marked with pencil to insure that my designs are centered.

Here are my jigs all loaded up and ready to rip on the table saw. Use a good sharp blade so you can join right away or keep your jigs in place and run it through the planer and thickness sander if you have one. Mine usually are joined with table say cuts only. A good blade makes all the difference. Mark the outside of your jigs with the lines of the designs from the inside so you know you are taking as much from the bottom of the ring design as the top.

Here they are all 8 just off the jigs with their bottoms and tops perfectly aligned. This perfect alignment is then the basis of the miter cuts to join them.

Again, a cutting jig is essential here to getting a good cut and safety. Also marking to center the design is the key. You can see my mark on the jig below the clamp. It is set for the center of the design not the edges of the piece. The center of the design is the standard to set your cut against. Before the saw is turned on your fingers should be far removed from the entire saw area and the piece should be locked down by clamping with a certainty it will not move or vibrate during the blade pass.

Here we see the cut off with design center lined up with the pencil mark. Keep these cut off’s !!! I have made funky and wonderful small projects (Christmas ornaments especially) with these. They are exact, witch means if you join them correctly they will fit together just as your ring will, making a clever little, whatever.

Here are the segments ready to make into a ring. At this point you can choose to further highlight or not. For example with these Ash rings I will make windows around each design by inserting another wood in between each design segment. On the Black Locust I will not.

This will begin to move rather quickly so I will try to let the pictures speak more.

Check for a good tight fit with no gaps before gluing. If you have less than perfect joints use the half ring method, forming and gluing up half circles and then sanding the two remaining joints to perfect fits. Much easier to work with two joints than 8.

Here the highlight rings have been glued up and are ready to go. Notice I inserted a piece of black Locust in between each of the ash rings to make the left and right sides of the windows

Now, finally after weeks we have something to put on the lathe. Centered we begin to add rings as we go. The top and bottom of course will be black locust in order to close our windows for each design highlight. Rings of Brazilian walnut help to further highlight.

The black locust vase will be plainer and less decorative by design.

I use a lot of weight instead of clamping. Make sure the weight is evenly distributed or it will show in wider than necessary glue lines. Check out my post on PVC for more info on that.

Here is the ash vase with the black locust windows and Brazilian highlights. All in all I think it came out good. Not great but a solid good.

Interior shot.

Here is the black locust with no extra highlights. My wife likes this one best. Sometimes less is defiantly more. For me I like the more complex designs and therefore the ash with highlights. Sometimes less is defiantly less, right?

Anyway, whatever your preference or design choice these steps can help you get something whose design is flat (cutting board) and design it into something round.

Keep turning and be safe

Steve

10/11/12